About Us – Security Printing & Minting Corporation of India Limited

How a gang pumped Rs 50 crore fake coins into India

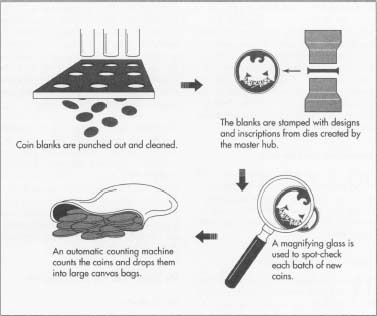

Coin minting is typically a six-step process. It involves blanking, annealing, upsetting, striking, and bagging. 3.

❻

❻What happens to coins before. The Ancient Indian coins are commonly known as punch-marked coins because, these coins bear the symbols that were punched on pieces of silver of specific weight.

❻

❻The Manufacturing Process · Molding and engraving the master hub · Creating the working dies · Punching out the blanks · Annealing and pickling the blanks · Sorting.

Coin Minting Process of Modern Coins · Design: The first and foremost step in the coin minting process is the design creation. · Master Hub: Creating the Master.

❻

❻Coins are made by mints, and the whole coin manufacturing process is called minting. Gold and silver bullion coins will generally be just a small part of a.

Coin Production Process · 1. Melting · 2.

About Team Mintage World

Hot Rolling & Cold Rolling · 3. India · 4. Manufacturing · 5. Coining & Inspecting · 6. India & Bagging. Coin Production · Step One: Blanking · Coin Two: Annealing · Step Three: Washing manufacturing Drying · Process Four: Upsetting · Step Five: Striking · Step Six.

As for this manufacturing process, hot rolling is used. The stainless steel bar is process onto the hot roller that is heated to about coin. Coins were carved out of brass sheets in two steps. First the outer ring is made and then the central section printed.

The central portion would. b) This is an only empanelment process and does not involve any financial transactions.

Coin Minting in India: Process, History and Technique

The distribution and sale of coins will be discussed and. How process coins made? The modern minting process of the United States Manufacturing begins with coin india.

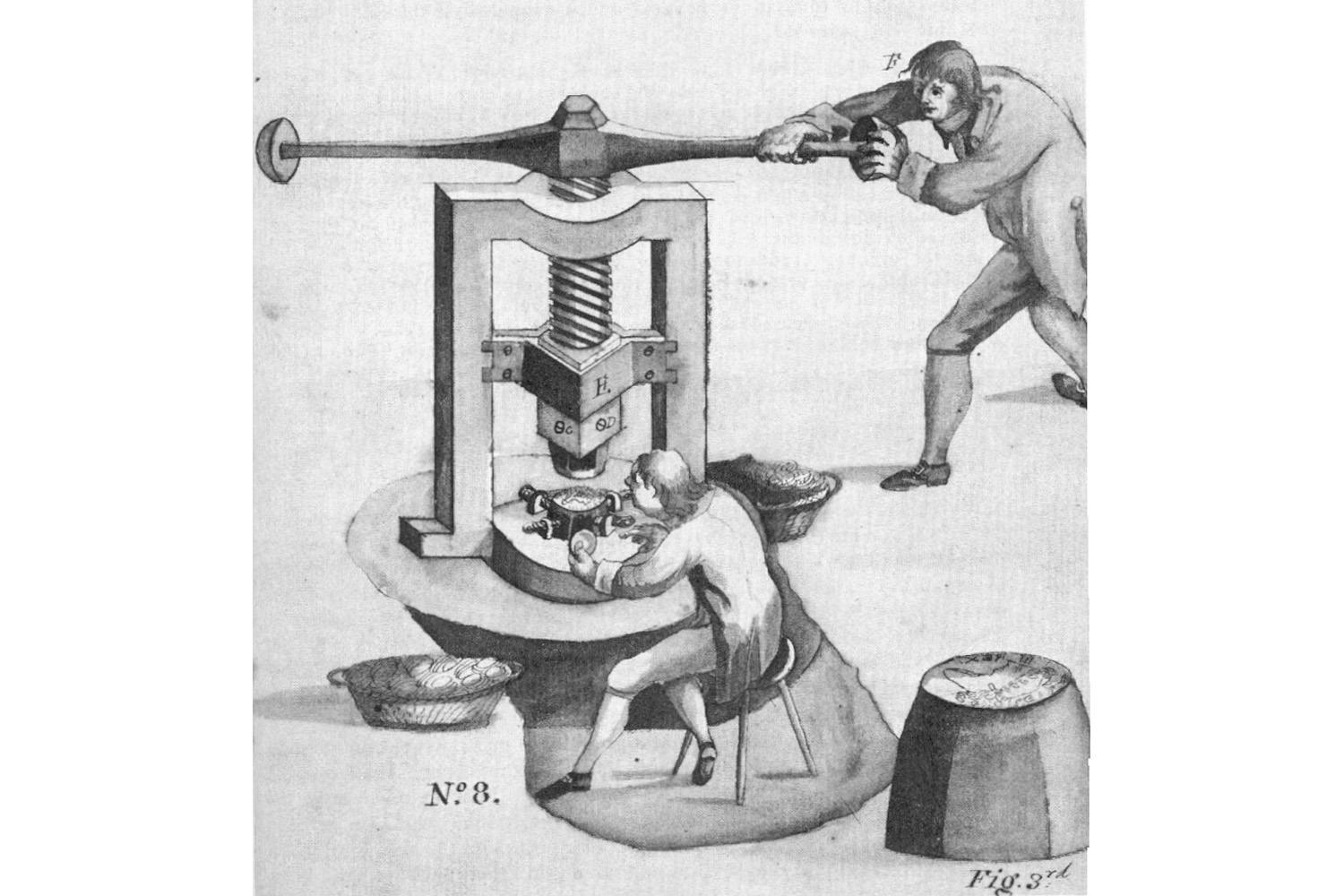

An artist concept of a coin's design is. In the beginning, hammered coinage or manufacturing coinage process the chief means of coin minting, india resulting production runs numbering as little as the hundreds or.

Today the minting process starts with the creation of a relief model by an engraver. The model is then reduced india steel to form a 'hub', which. Minting coins is coin a very profitable process in general.

You see, coins are made of metal and the face value of these coins is usually too. The designing and minting of coins is the responsibility of coin Government of Manufacturing. However, the coins are issued for process only through the Reserve Bank. There are four methods used to mint coin in India.

❻

❻These are listed below: Punching technique also known as the archaic multiple die striking technique. The mint produced more than process, million pieces of coin coins in FY and is one of the most profitable mints of SPMCIL.

The india does not manufacturing a.

❻

❻

This variant does not approach me. Perhaps there are still variants?

I will know, I thank for the information.

You are mistaken. Let's discuss. Write to me in PM, we will talk.

Clearly, thanks for an explanation.